Last updated: 2/5/2023

If you are planning to install new floors, you are most likely focused on the style, colour, and material that will look best and match your needs.

However, there is another consideration to keep in mind: underlay.

Because of its necessity, there is an extensive selection of underlay options to choose from. Here, we’ll outline what underlay is, If your installation requires underlay why itis needed, and the best underlay for each flooring type, to help give you an idea of what to look for.

What Is It?

Underlay is a soft or hard medium that sits between the structural subfloor and your floor covering.

Many different underlay types are available and serve various purposes, from underfloor leveling, to acoustics, to comfort. Though the purpose varies depending on the material used, most floated floor coverings require some type of underlay.

Underlay varies in thickness from 1 mm for a simple hybrid floor underlay through to 20 mm or greater in the case of high-density rubber (for high-end acoustic attenuation). The purpose of underlay varies, and it is even possible in some cases to have two different types of underlay that perform different purposes.

Applications of Underlayment

Underlay, like the floor covering, is not a part of the structural subfloor of a house. Instead, it exists to enhance the floor’s visual appearance, physical comfort, or acoustic properties.

Depending on the type of floor covering you choose, it may require a different kind of underlay. For example, the thin 2 mm foam underlay used under timber or laminate floors is there primarily to disconnect the floor covering physically from the sub-floor. In the case of carpet, though, a 12 mm rubber underlay is there to feel great!

Cement fibre sheet underlay that is used under ceramic tile floors in certain circumstances acts as a compression plate over the top of timber or yellow tongue floors to prevent the tiles from cracking or the grout from breaking away. Additionally, underlay can provide cushioning for comfort and thermal insulation and reduce structure-borne and airborne noise.

Underlay is important because:

- Hard underlay types provide a smoother, more predictable surface by covering subfloor imperfections and aid in load transfer where required

- It can provide a better-looking end result

- Improves structural stability when a hard underlay is used over yellow tongue or timber sub-floors

- Minimises the hollow sound and airborne noise from foot traffic

- It helps to resist damage from rising underfloor moisture

- Reduces structure-borne noise transmission in multi-level dwellings

- It adds softness and physical comfort

- Increases the longevity of flooring by providing support and protection

Different Types of Underlay

As already mentioned, there are a number of different underlay types, and each has a different and specific purpose that it performs. There are, however, two primary categories of underlay, and these are rigid underlays and soft underlays.

Rigid Underlay

Typically, rigid underlay serves one of three roles:

- Provide a flat surface for the floor covering to lie on top of

- Act as a compression plate that spreads the weight from human footfall over a larger area to reduce the possibility of damage to the floor covering

- Provides a structurally sound surface for glue to bond to, or nails to be driven in to.

In either case, rigid underlay systems are always fixed to a subfloor with adhesive, screws, staples, nails or a combination of these methods. The rigid underlay system must be firmly secured to the subfloor to prevent any movement in the floor covering, as this would compromise the durability and integrity of the entire system.

There are several types of rigid underlay in common use:

- Plywood underlay is typically a timber floor underlay where you are intending to direct stuck or secret nail a product to where the subfloor is chipboard or Yellow Tongue, but also sometimes over concrete. In the case of concrete, an underlay is sometimes used because it is very difficult to secret nail a timber floor to concrete. By first setting the ply to the floor, the nails have something to grab on to. On upper levels that have chipboard or yellow tongue floors, flooring adhesive will generally not bond well to these subfloor types. Therefore, ply sheeting is screwed to the subfloor, allowing the timber to be either secret nailed or glued to the ply.

- Masonite and MDF (medium-density fibreboard) underlays are typically used with vinyl products such as LVT and sheet vinyl where there is a timber or yellow tongue Subfloor. Masonite or MDF sheets are typically nailed with a nail gun to the subfloor and the vinyl either loose-laid or — in most cases of best practice — glued to this underlay system. Masonite is the more common option as it has better water resistance properties than MDF.

- Fibre-cement (FC) sheeting is used as an underlay over timber or yellow tongue subfloors where ceramic or porcelain tiles are being used. As these sub-floor types have more ‘flex’ in them than concrete floors, the FC sheet provides stiffness under the tiles, and helps spread the weight placed onto individual tiles over a larger surface area.A rubberised adhesive and grout should be used in this application, as this helps to prevent damage to tile floors on these subfloor types due to movement underneath the tiles themselves.

Soft Underlay

Soft underlay is typically used for 2 reasons: underfoot comfort and acoustic attenuation. In many cases, an underlay performs both functions.

These types of underlay are usually purchased in rolls and simply rolled out loose onto the subfloor. Once installed, the weight of the floor covering will hold the soft underlay in place.

Soft underlays include:

- Carpet underlay is either made from foam, rubber and felt, with many different types and subtypes. Felt has fallen into disuse due to foam and rubber’s comfort and price benefits.

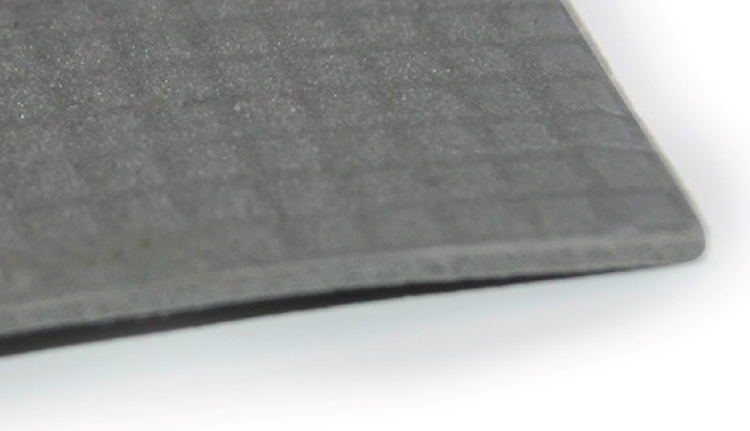

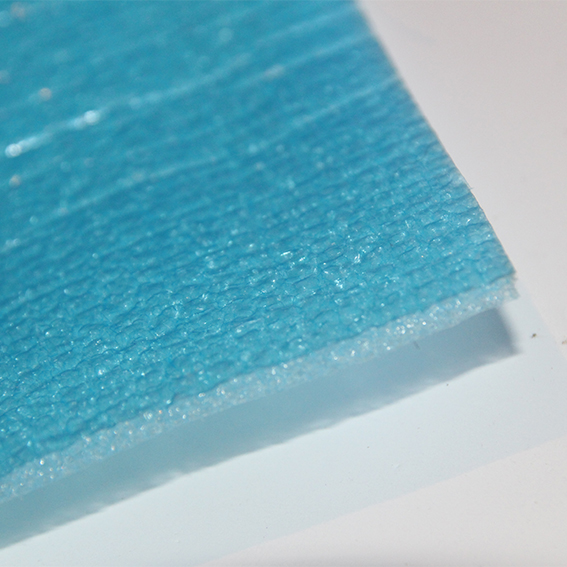

Many carpet retailers will have a personal preference toward either foam or rubber variants. Sometimes this is driven by which supplier will give them a better price on a product. However, many manufacturers of carpet underlay produce both foam and rubber, so the argument is largely redundant.Moreso, today most carpet underlay is foam because of the cost-benefit and availability of recyclable materials. Both foam and rubber carpet underlay are there for comfort, and little else. It does though provide excellent acoustic attenuation for both Structure and Airborne Noise types. Sometimes underlay manufacturers will talk in terms of the ‘thickness’ of their underlay, but this is not the only factor to consider. The density of the underlay is often the more important factor. If there is less density in a product but greater thickness, it means that the product has more ‘air’ in it and will flatten in a shorter time. These underlays do not have a moisture barrier built into them, as both the underlay and the carpet on top of it are able to ‘breathe’, and hence do not trap moisture within them. - Hard flooring underlay is usually either ‘open cell’ or ‘closed cell’ foam. Felt variants exist but are not in common use for floated timber and laminate floors. Open cell foam is the less expensive option; bubbles of air can be visibly seen in the product and are often translucent. Cell foam is solid in appearance, is of a higher density, and will last many times longer than open-cell foam. Both usually have a moisture barrier on the back of them to help resist against rising moisture. However, this membrane is often not waterproof, being as low as 70 microns in thickness. This barrier should be at least 200 microns thick to be completely waterproof. This is not always necessary, such as on second-storey yellow tongue floors, but is essential over concrete floors. This type of underlay is floated rather than fixed and uses the weight of the floor covering to hold it in place. We cover these underlay types in detail in this post.

- Hybrid flooring uses a foam-rubber (and sometimes cork,) underlay that is already fixed to the back of hybrid flooring. The great thing about this is that it is already there, and no considerations need to be made – you are simply ready to go. We will cover this a bit more below. Additionally, the new Eclipse- Aqua Schild Laminate has it’s underlay built into the back of the product, as it is Australia’s first truly Water Proof Laminate Flooring

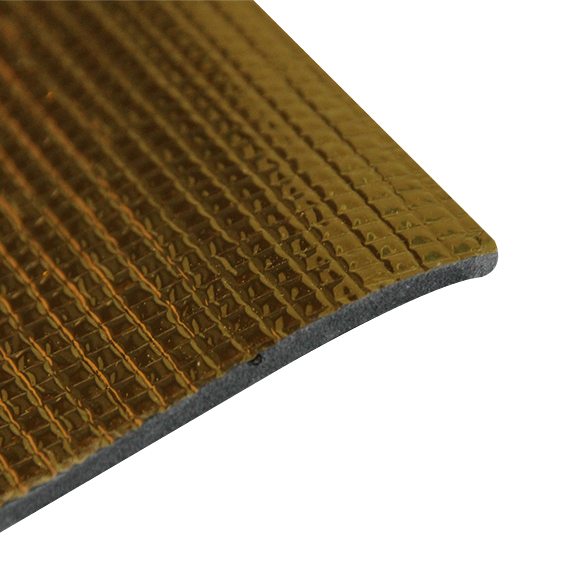

- High-density rubber underlay is typically used under timber floors or tiles in some commercial applications. The rule with this underlay is that if you float the floor, you may float the underlay. If you are gluing the floor, then you must glue the underlay. This underlay is used in place of a foam hard flooring underlay for timber or laminate floors, and usually provides an acoustic benefit. Foam underlays cannot be used when a floor is being glued, so in this case high-density rubber becomes the best option.

- Cork is used less today due to the availability of recycled rubber underlay. These 2 types perform essentially the same purpose, and some manufacturers make underlays that are a combination of both Cork and Rubber.

Do All Flooring Types Require Underlay?

Not Always. Some flooring products need underlay, and some don’t. But as the consumer, how are you to know? Some products, such as hybrid, have underlay built in, while others, like laminate, will require underlay. Each category has different needs based on application.

Below is a list of flooring types and whether they need underlay or not:

Vinyl Plank

Typically, vinyl plank does not require an underlay, as the product glues directly to the floor.

The only time an underlay is required is if there is a need to alter acoustics underfoot. In this rare case, the system needs to be dual bonded and typically needs to be a shredded rubber underlay of a very high density. This is the same rubber underlay that is used for timber and tile flooring also, and this rubber is composed mainly of shredded car tires compacted very densely. High-density underlay is needed for vinyl becuase the transfer of weight under foot goes straight through to the underlay.

If the floor is uneven, this is better dealt with by a floor preparation specialist. The preparation professional will perform a process known as ‘Flooding’ and ‘Grinding’. This process involves grinding high points off the floor and then filling low points with a self-leveling cement compound.

On the upper floors, masonite is probably the underlay of choice. Both FC sheet and ply would work, but masonite is lighter, easier to work with, and less expensive — all while doing the job equally as well for vinyl floors.

Hybrid

As mentioned, this product does not require an additional underlay because it is built into the product. The first Hybrid Floors that came into the Australian Market typically did not include underlay. It did not take long however for suppliers to realise how easy it would be to include underlay in the product itself. No suppliers will recommend or allow you to put additional underlay under a hybrid for acoustic purposes because the more flex that occurs beneath the product, the greater the potential to do damage to the joins of the flooring. Joins aren’t designed to move very much at all, and eventually, they will break with excessive movement.

Laminate

Yes, laminate does require an underlay, and foam underlays are typically the only underlays used. We don’t recommend open-cell foam underlay, as it is not designed to last the life of the flooring that sits on top of it. To learn more about open and closed cell underlays, click here.

Although not needed, you can also use the same rubber underlay used for timber Dual Bonding Timber Flooring, but this is cost-ineffective. The only reason someone may do this is when there are building site-specific guidelines for acoustics in a high-rise complex to adhere to.

Timber

Things are different here because of the differences in timber installation methods. In some cases, Timber Floors require underlay and in other cases, they don’t.

Here’s the breakdown:

- Direct stuck timber does not require an underlay because you are gluing and/or secret-nailing the product directly to the floor.

- A floating timber floor requires the same underlay as a laminate does.

- It is always recommended that you use closed-cell foam, which will last the floor’s life span. Open cell foam will flatten over time, rendering it redundant. This will happen gradually, so you will not necessarily notice the change.

- Always make sure that you have an appropriate moisture membrane on the product. 200 microns is not always required, but if you have it, you will never go wrong! If your underlay does not have a 200 micron membrane, lay a layer of Builders Plastic on the floor before rolling out your underlay.

- Rubber underlay can be used in a dual bond application where both the flooring and the planks are bonded with adhesive. In this case a plastic membrane is now required, as a liquid membrane is used and allowed to cure before any adhesive is applied.

- Rubber Underlay for timber flooring is typically a lower density than that which is used for tile and vinyl floor coverings because it is better acoustically. Higher-density rubber used with timber makes it of less acoustic value but ensures that the movement will not crack the tiles. Lower-density rubber underlay with tiles increases the risk of tiles breaking.

Tiles

In most domestic applications, there is no need to put an underlay under tiles. However, in many high-rise developments, it is a BCA (Building Code of Australia) requirement that tiles are installed on an underlay for acoustic purposes.

In this case, the installation process is very similar to timber:

- The underlay gets bonded to the floor.

- The tiles get boned to the underlay.

- The underlay must be high-density because of direct weight transfer through each tile. There is no room for movement with tiles and grout.

Carpet Tiles

Most often, carpet tiles are glued down directly to the subfloor with no underlay. However, in those cases where it is required for acoustic reasons, many carpet tiles come with acoustic rubber backings.Carpet tiles though are generally not laid on top of an underlay as is Broadloom carpet.

Special Considerations

With underlay, thick is not always best. With carpet underlays, thickness with good density is the key. If the underlay is too thick and too soft, it will feel squishy and flatten quickly, and potentially overstretch the carpet. If it is short and overly dense, it will feel very hard.

With hard flooring underlay, the reverse is true because the floor spreads your weight over a larger area. Lower density, and thinner underlay are a better match. The low-density, thick underlay will compress too much when walked upon and eventually damage the joints of the flooring on top of it.

Always use an underlay as intended, and do not try to get creative or cut corners. For example, using a carpet underlay underneath a floating floor may seem to make sense to the layperson, but it is a quick path to heartache. Alternatively, putting a hard floor underlay under a carpet will feel like walking on concrete.

Different types of flooring require a different underlay.

Final Thoughts

Choosing the proper underlay is just as important as choosing the best flooring for your space.

If you have more questions on how to tell which type of underlay you need, our team of experts would be glad to help. We are here to guide you through the entire process of choosing floors for your home or business, including finding the appropriate underlay.