Last edited 24/5/23

LVT (Luxury Vinyl Tile,) Flooring has been a popular flooring option for years. However, with the rise of Hybrid Flooring, LVT has taken a back seat to the new kid on the block.

As consumers continue to demand affordable, waterproof, aesthetically pleasing flooring solutions, a host of advanced flooring options, such as rigid core (SPC and WPC) hybrid flooring, have become increasingly popular.

While these are three separate three-letter flooring products, they actually represent only two separate flooring categories, although they are all easily confused. Each has had its pros and cons, but two of these products have been far more successful than the other for reasons we will outline.

When comparing traditional LVT with options such as SPC or WPC Hybrid, there are several key similarities and differences to consider. To learn more about how these flooring options differ from one another, it is first important to understand what each type is.

Here, we’ll compare each type in-depth to help you determine which kind will best fit your needs:

What is LVT Flooring?

The eldest category of the three LVT (Luxury Vinyl Tile) is an innovative, updated version of the old sheet vinyl flooring, or ‘Lino’ that your parents or Grandparents may have had. Its realistic designs mimic the look of real wood, ceramic, or stone flooring while still being affordable. LVT is commonly referred to as Vinyl Plank or simply ‘Plank’ and is made of multiple layers of flexible vinyl (and, in many cases fibreglass) that glues directly to your subfloor.

LVT flooring mimics the look of real wood, ceramic or stone flooring.

This once massively popular flooring option is also hard-wearing, scratch-resistant, and waterproof, making it a top contender for any room in a home or commercial space. LVT flooring, such as our popular Nature’s Own and Nature’s Best, consists of multiple thin layers that offer flexibility, durability, and low maintenance.

What Is SPC Hybrid Flooring?

SPC (Stone Polymer Composite) rigid core hybrid flooring has largely replaced LVT as the most popular flooring product category. In Australia, this product sits in a category called ‘Hybrid’ unlike other countries, where it is usually known as RVP or Rigid Vinyl Plank.

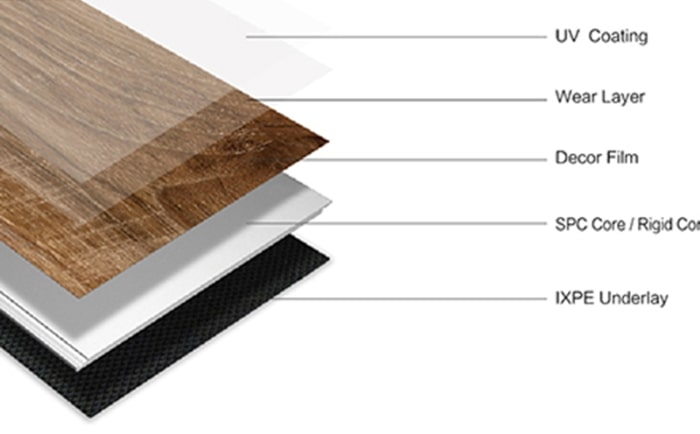

SPC flooring consists of several layers:

- UV coating

- Wear layer

- Picture film or ‘Decor’

- SPC core

- Acoustic Backing

SPC boasts minimal noise when walked on, no distortion or warping, heat and sound insulation, and no harmful emissions. It is also eco-friendly, and completely waterproof.

SPC flooring has a click-together locking system and installs like any floating floor.

SPC flooring is an upgraded version of LVT.

What is WPC Flooring?

In essence, WPC (Wood Polymer Composite) or aerated core closely resembles SPC but features a core typically composed of polyvinyl chloride, a foaming agent, calcium carbonate, wood-like or actual wood materials such as wood or bamboo flour, and plasticisers.

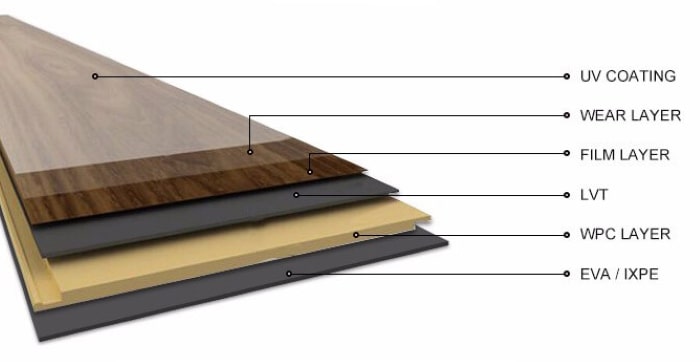

WPC flooring consists of several layers:

- UV coating

- Wear layer

- Picture film or ‘Decor’

- 1mm vinyl layer

- WPC core

- Acoustic Backing

WPC floors are becoming an increasingly popular option for replacing various wood materials.

While very similar in its construction to SPC Flooring, there are two fundamental differences these products:

- WPC Flooring utilises a Foaming agent that Aerates the core. The core of SPC is solid

- WPC includes a 1mm vinyl layer that sits between the picture film and the core of the product.

This makes the core of a WPC Floor up to 41% lighter than an SPC core of the same thickness. The additional vinyl layer is necessary to protect the picture film from the bubbles in the core, a byproduct of the Aerated Core.

Which Option is Best for You?

| WPC | SPC | LVT | |

|---|---|---|---|

| Fade Resistance | Moderate | Moderate | Moderate |

| Wear Resistance | High | High | High |

| Stain Resistance | Moderate | Moderate | Moderate |

| Dent Resistance | Moderate | High | Moderate |

| Scratch Resistance | High | High | Moderate |

| Moisture Resistance | High | High | High |

| Care | Easy | Easy | Easy |

| Installation | DIY Friendly | DIY Friendly | Requires Adhesive |

| Dimensional Stability | Moderate Stability | Very Stable | Unstable- Requires Adhesive |

An In-Depth Look at WPC vs SPC vs LVT Flooring

Let’s take a look at 15 of the differences and similarities between WPC, SPC, and LVT vinyl flooring.

1. Structure

All three of these flooring types are composed of different layers, but the layers vary between types.

SPC Hybrid Flooring consists of the following layers:

- UV Stabilised Polyurethane PVC Wear Layer

- Picture Film

- SPC (Stone Polymer Composite) Core

- Foam, Rubber or Cork Underlay

WPC Hybrid Flooring consists of the following layers:

- UV Stabilised Polyurethane PVC Wear Layer

- Picture Film

- 1mm Vinyl Layer

- WPC (Wood Polymer Composite) Aerated Core

- Foam, Rubber or Cork Underlay

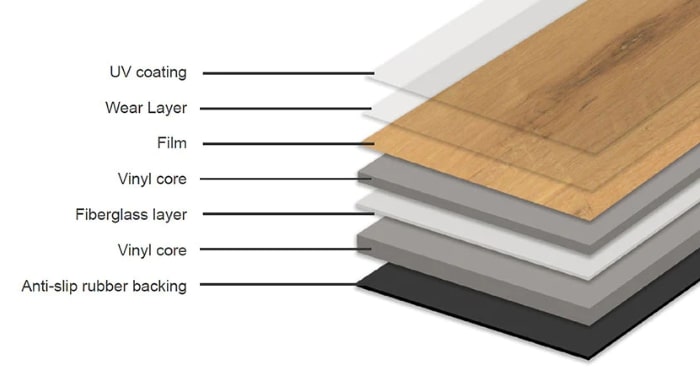

LVT Flooring consists of the following layers:

- UV Stabilised Polyurethane PVC Wear Layer

- Picture Film

- Multiple Layers of Vinyl

- Fibreglass layers (only in top end 4.5mm and 5mm products)

- Backing layer

2. Construction

The most visible in the construction of these products is that LVT is Flexible and lacks a loving system and must therefore be glued to the floor. WPC and SPC Floors are Hybrid Floors that are rigid and lock together.

3. Plank Thickness

- LVT Floors, because they glue down, are typically the thinnest type. The range between 2-5mm in thickness

- WPC Floors typically start at 6.5mm thick and go upwards from there. WPC needs to be fairly thick as the aeration of the core makes thinner joins weaker.

- SPC Floors range from 4.7mm to 9.7mm in thickness. SPC Floors are able to be thinner because they are solid

4. Sturdiness

Due to differences in the core materials, SPC tends to be the most dimensionally stable of these options. The sturdiness also helps the floor feel more solid and increases its defence against wear and dents. This also makes it the heaviest product out of the three but well worth any increased freight costs.

5. Appearance

All 3 of these categories utilise the same technologies in their picture films and wear layers. In fact, they are all the same

WPC and SPC hybrid flooring has in some cases, made use of Embossed in Register (EIR) technology but has not been adopted on a large scale, as it has simply not had to. As a market leader, we firmly recommend Eclipse Stone-Tek as the most realistic hybrid flooring product on the market due to its quality printing, pattern repeats and use of brilliant EIR technology.

LVT planks tend to be a little shorter than Hybrid planks. The average length of an LVT floor is 1.2m with a maximum length of 1.5m. The average length of a Hybrid floor is 1.5m, and goes up to 1.8m. You, however, will not be disappointed with the look and price of a product such as Nature’s Best in our Eclipse Range.

6. Subfloor

The requirements for subfloor preparation are the same for LVT and Hybrid Floors but for two different reasons. LVT is flexible and can ride subfloor imperfections. However, every imperfection will be visible through the plank over time.

Hybrid Flooring is unconcerned with small imperfections like divots and grout lines as it has the strength to bridge these successfully. It is concerned, though, with height differentials, as it will bridge high points and create unsupported hollow areas between these high points.

7. Installation

Any of these flooring options feature DIY potential. All WPC or SPC hybrids feature a click-and-lock system that eliminates the need for nails or glues. LVT planks must be glued to the floor.

8. Comfort Under Foot

Oddly, here things are the reverse of what you might imagine.

LVT is Flexible, and you would imagine it is softer underfoot. However, as it bonds to the sub-floor, it has remarkably little give, and feels quite hard. You will notice this in your local supermarket when you are walking around.

SPC and WPC on the other hand have an underlay that sits between the rigid core and the sub-floor. This gives the floor a lot more comfort than you would at first think underfoot.

9. Dent Resistance

Traditional LVT floors are pliable and soft, making them an easy target for dents from heavy furniture.

Thanks to its rigid core construction, a WPC hybrid is less likely to dent. However, it is still a softer flooring that is not entirely safe from the threat of dents.

Comprised primarily of stone, SPC hybrid features superior resistance to dents when compared to LVT and WPC.

10. Price

LVT and SPC Flooring is comparatively priced in most cases, although LVT has a lower low end due to the construction. SPC has a higher high end as more can be done with the product, where LVT has an upper limit to what can be done in it’s construction.

WPC is similar to SPC, but is typically more expensive. While the Material in the core of the SPC is slightly more expensive, the WPC requires an additional vinyl layer, and this makes the construction more labour-intensive, which is reflected in the pricing.

11. Waterproof

All three types of these floors — SPC, LVT, and WPC — are waterproof. Little more to say here.

12. Environmentally Friendly

None of these options are great friends to the environment, as they all have PVC in their construction. SPC, though is the lesser of these potential evils

LVT and WPC floors both utilise plasticiser in their formulation. Otherwise, none of these products can claim to be great friends of the environment.

13. Application Area

Like most vinyl flooring, WPC and SPC vinyl can be installed above and on grade. They can also be installed in wet areas like bathrooms, kitchens, and commercial spaces.

Generally, WPC and SPC Floors are more suitable in a residential area as they are floated floors. LVT vinyl is well suited for commercial applications because it sticks to the floor and cannot move under a huge traffic volume.

LVT can still be used residentially successfully, and Hybrid in commercial spaces should be limited to smaller areas and light commercial use.

14. Maintenance and Cleaning

Cleaning and maintenance are simple with WPC, SPC, and LVT flooring. All it takes to maintain great-looking floors is regular sweeping and an occasional deep clean.

15. Temperature Fluctuations

If temperature fluctuations are a concern, SPC vinyl will offer superior performance compared to WPC or LVT flooring.

LVT is inherently temperature sensitive, hence the need for it to be glued. WPC, due to its aerated core, is also prone to growth in extreme heat situations. With its LImestone core, SPC is easily the most stable of these three flooring types.

Need Further Help?

After reading this article, you will know which flooring suits your requirements.

If you have further questions or want additional advice on WPC, SPC, or LVT flooring, please contact us. One of our experienced flooring professionals would happily help you and guide you through the process.