After decades in the industry, I can tell you that most “flooring failures” aren’t caused by bad products; they’re caused by how and where those products are installed. The good news is that the biggest flooring problems are preventable if you understand what’s really going on under your feet.

In this guide, I’ll walk you through why different flooring types fail in Australian conditions, what’s changed over the years, and the simple things you (and your installer) can do to avoid expensive headaches.

In Summary

- Most flooring problems are site-related, not product faults. Most modern laminate, vinyl, hybrid, timber and bamboo products are well-made. Failures usually come from uneven slabs, moisture issues, building movement or ignoring the installation guide.

- Subfloor preparation is non-negotiable. New slabs often have more dips than a BMX track. If the subfloor isn’t within the manufacturer’s tolerance, you’ll likely see peaking joints, movement and gaps in rafted floors like laminate, hybrid and floating timber.

- Moisture is the silent killer. Moisture rising through concrete (or from burst pipes and damp sites) can cause swelling, joint damage and delamination. Builder’s plastic or the correct rolled-on moisture barrier prevents most of these issues.

- Acclimatisation prevents a lot of heartache. Timber and bamboo need time to adjust to your home’s environment before being laid. I’ve seen entire towns where one retailer had zero issues simply because they forced people to acclimatise properly.

- Each flooring type has its “weak point”. Early laminate struggled with moisture ingress, loose-lay vinyl moved with temperature, bamboo exaggerated climate changes, and thin hybrids can struggle on second-storey bounce. Knowing these quirks helps you choose the right product.

- Follow the manufacturer’s rules to keep your warranty. Raft size limits, expansion gap requirements, adhesive rules and silicone restrictions are not suggestions. If you go outside them, your warranty is compromised, even if the product is perfect.

- Prevention is cheaper than repair. Spending a little extra on levelling, moisture barriers, correct adhesive and the right product thickness is always cheaper than pulling up a failed floor later.

Flooring Problems Across All Categories

Nearly every time I’ve been called to a “flooring failure,” the real issue has been the site, the subfloor, or the way the product was installed.

Let me break down the big ones, because these problems affect every flooring category, including laminate, vinyl plank, hybrid, timber and bamboo, just in slightly different ways.

Site-Related vs Product-Related

If only I had a dollar for every time someone said, “There must be something wrong with the product.”

Most of the time, the product is fine. Even the lower-cost products these days are made surprisingly well. This elephant in the room can be hard to accept if you are in this situation, facing issues.

The problems usually come from:

- Moisture in the slab

- Uneven subfloors

- Building movement

- No expansion gaps

- Installing outside the manufacturer’s raft size

- The wrong adhesive

- No acclimatisation

- Or simply not following the installation guide

Product faults do happen — but they’re very rare. When they do happen, suppliers quarantine that entire batch immediately. When I was at Signature, we had one hybrid batch where the locking system was off. We quarantined the lot. It cost less to pull it out of circulation than to replace floors.

So yes, manufacturing issues exist… but they’re the exception. Site-related issues are the rule.

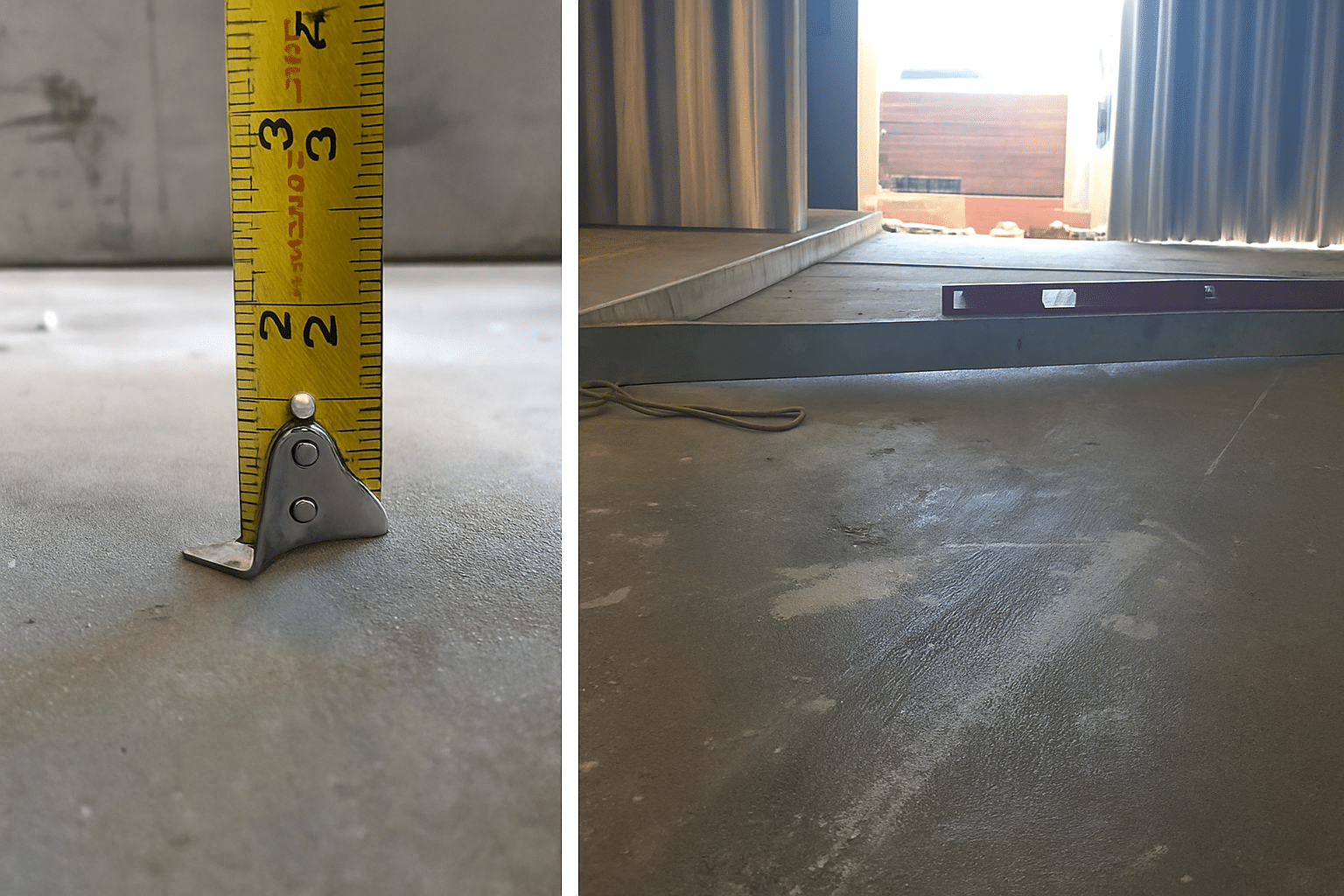

Uneven Subfloors and Slab Flatness Problems

This is the big killer, especially for rafted floors like laminate, hybrid and floating timber.

I know this frustrates people, but it’s the reality:

New slabs are not necessarily poured to flooring standards.

Builders pour slabs to their own standards, and those standards are nowhere near the tolerances flooring manufacturers require. I’ve seen brand new homes where the slab had more dips than a BMX track.

Your floor might look flat to the naked eye, but as soon as you run a straight-edge over it, you find the highs and lows — and that’s where the trouble starts.

Uneven slabs lead to:

- Joint peaking

- Clicking noises

- End joints opening

- Movement in boards

- Bounce underfoot

- Premature failure of locking systems

If you’re installing a rafted product, anything outside the manufacturer’s tolerances will eventually lead to problems.

We recommend reading this guide to learn more about the importance of subfloor preparation.

Measuring concrete subfloor tolerance using a tape measure and a straightedge to show height variations before installing flooring

Moisture in Concrete Slabs and Rising Damp

Moisture is the silent assassin of flooring. It doesn’t announce itself it creeps up through the slab, sits in the joins, and slowly eats away at the weakest parts of the floor.

Over my career, I’ve seen it all:

- Swelling edges in laminate

- Joint damage in hybrid

- Vinyl adhesives letting go

- Timber expanding well beyond seasonal movement

- Bamboo going wild and lifting

And the saddest part? Almost every one of those jobs could have been saved with a simple moisture barrier.

This is what rising damp looks like. If you lay flooring over this without a proper moisture barrier, you’re asking for heartbreak

When you’re dealing with concrete slabs, especially in older homes or areas with clay soil or groundwater issues, your best friend is:

- Builder’s plastic (for floating floors)

- The correct rolled-on moisture barrier (for direct stick installations)

Skipping this step is like building a house without a roof.

If you need detail on how to correctly “tank” a floor using builder’s plastic (which I strongly prefer), that’s covered in-depth in our laminate and timber installation resources.

Building Movement and Second-Storey Bounce

This one catches a lot of people off guard.

If you live in a home that’s:

- Built on posts, or

- Has a second storey with chipboard or yellow tongue,

Your building will naturally have more twist and more bounce. You won’t feel it underfoot, but your flooring will.

When a rafted floor is 10, 15 or 20 metres long, that tiny bit of movement transfers energy into the floor. That energy looks for the weakest point, which is usually:

Hallways, corridors and narrow sections of flooring.

I’ve seen:

- Joints opening

- Peaking

- Edges lifting

- Boards misaligning over time

This isn’t a product fault. It’s just physics, and it’s why choosing the right product thickness matters hugely on upper levels.

Expansion Gaps Done Wrong (or Not At All)

Expansion gaps are one of those things everyone thinks they understand until they don’t follow them properly.

Here’s the reality:

- Laminate expands.

- Timber expands.

- Bamboo expands even more.

- Hybrid won’t grow much, but it still needs room to move.

Expansion gaps stop your floor from turning into a giant pressure cooker.

When the floor has nowhere to go, it bows upwards, and suddenly you’ve got a hump in the middle of your living room that looks like a speed bump.

The mistakes I see most often:

- No expansion gap at all

- Expansion gaps is too small

- Benches or cabinetry installed on top of floating floors

- Silicon filling the expansion gap

- Hybrid was glued at the edges by accident

- Skirting boards or trims nailed into the floor, pinning it down

Just follow the manufacturer’s rules. They’re not guessing; they’re telling you the exact requirements to avoid failure. And most importantly, make sure your installer follows them.

Incorrect Adhesives and Bad Installation Practices

This one mainly affects vinyl plank and timber, but it can ruin any job.

Examples I’ve seen over the years:

- Using a pressure-sensitive adhesive where a hard set is required

- Skipping the moisture barrier before direct stick timber

- Laying vinyl planks without acclimatisation

- Installing rafted floors outside the maximum raft sizes

- Installers butting boards too tight or too loose

- Using silicone where it voids the warranty

- Laying floors the same day they come out of a cold truck

Every manufacturer has a guide. Every guide exists because someone in the past didn’t follow it, leading to failure.

If the installer ignores the rules, the warranty is gone instantly.

Why Flooring Warranties Are Voided Regularly

People get upset about this, and I get it.

But here’s the truth:

A flooring warranty covers manufacturing defects — not installation issues and not site conditions.

If you:

- Don’t level the floor within tolerance

- Don’t use moisture protection when advised

- Don’t acclimatise timber or bamboo when advised

- Silicone the perimeter when you’re not allowed to

- Exceed the recommended raft size

- Don’t leave enough expansion gap

- Choose the wrong product for a second storey

- Lay over a slab that’s still curing

Then you’re outside the installation requirements. It doesn’t matter how good the product is; it’s been installed in a way that guarantees early failure.

Flooring Issues by Category

Every flooring category has its own personality and its own way of misbehaving when the conditions aren’t right. Hybrid fails to laminate differently. Vinyl fails differently again. Timber and bamboo each have their own set of rules. The issues can vary widely across categories, and most of them require more explanation than we can give in a single section.

That’s why we’ve covered the short version here, and we’ll be breaking down each category’s problems in dedicated blogs as well. For now, this section gives you a quick overview of what typically goes wrong with each floor type, why it happens, and the installation choices that prevent those headaches entirely.

Issues with Hybrid Flooring

Hybrid arrived as the “perfect floor”, waterproof like vinyl, tough like laminate and stable like SPC. And while it’s a great product, it still has a few weak spots, especially when the subfloor or site conditions aren’t right. We’ve written a full in-depth guide on hybrid problems, but here’s the short version.

The biggest issue is moisture coming up through the slab. If the concrete is still curing or holding moisture, it slowly softens the locking system at the joins, causing peaking, chipping or joint failure. That’s not a product defect, that’s a site issue.

- Moisture or chemicals rising from the slab

- Bounce or movement on upper storeys

- Subfloors outside flatness tolerance

- No builder’s plastic or moisture protection

- Expansion gaps blocked or siliconed shut

Hybrid is stiff, so if it’s forced to follow dips in the slab or laid upstairs with a thin core on a bouncy substrate, the pressure builds at the joins until something gives.

If you want the deeper breakdown, including thickness rules for second storeys and how different core types behave, we cover that in a full separate guide.

| Hybrid Issue | Main Cause | Simple Fix |

|---|---|---|

| Joint softening / breakage | Moisture rising from slab (silica hydrosis) | Use builder’s plastic under every install |

| Peaking edges | No expansion gaps / trapped perimeter | Leave correct gaps & avoid silicone |

| Movement upstairs | Bounce from chipboard or yellow tongue | Use thicker hybrid (7–10 mm) |

| Joint stress | Dips or humps in slab | Level the subfloor properly |

Expert Insight: Alkalinity Hydrolysis

Hybrid’s biggest enemy isn’t always water; it’s the alkaline vapour coming out of a concrete slab. That vapour can creep into the joins and slowly weaken the polymers in some hybrid cores, causing peaking or joint failure. It’s not a product defect; it’s chemistry. And the fix is simple: always lay builder’s plastic over concrete. For the full explanation, including which hybrids are most at risk, read the full guide here.

A Deeper Look

If you want the deeper breakdown, including thickness rules for second storeys and how different core types behave, we cover that in a full, separate guide. If you’re dealing with hybrid issues already, or you want to understand every weak point before you lay it out, our full hybrid problems guide walks through the real causes, what they look like on-site, and the simple fixes that actually work.

Read the full guide: Problems with Hybrid Flooring and How to Avoid Them

Laminate Flooring: Common Issues

Laminate only earned its bad reputation because of what happened in the early 2000s. Cheaper products hit the market at the same time the industry stopped using builder’s plastic under the floor. Without that waterproof layer, moisture crept into the joins, cores swelled, and we ended up with the “puffy edge” laminate everyone remembers.

- Moisture rising through the slab

- Raft size limits ignored

- Boards laid without acclimatisation

My rule with laminate is simple: tank the floor. Lay builder’s plastic over concrete, run it up the walls, install the underlay and trim it back at the end. It costs almost nothing and prevents most historical failures.

Scratch resistance was another past issue. Older lower AC ratings looked clearer but marked easily. Modern AC4 and AC5 laminates have solved that—great clarity, far better durability, and none of the foggy look older products had.

Done properly, laminate has gone from “problem child” to one of the best value floors on the market. Please protect it from moisture and follow the installation rules, and it performs incredibly well.

Issues with Vinyl Plank Flooring

Vinyl plank took off because it was “waterproof,” and it is; but waterproof doesn’t mean the floor won’t move. Early loose-lay versions were the big problem. They worked fine in cooler European climates, but in Australian homes, the PVC reacted far more to heat and cold, and the backing simply couldn’t hold the planks still.

- Planks shrinking in colder months

- Expansion in warmer months

- Loose-lay backing losing grip

- Dirt stopping gaps from closing again

The industry eventually moved to the real fix: use a full hard-set adhesive. Hard-set locks the boards down, controls expansion and stops seasonal gapping. Pressure-sensitive adhesive still has a place, but not in homes with wide temperature swings.

Vinyl also needs the right conditions underneath. A level subfloor prevents bumps from telegraphing through, and a dry slab makes sure the adhesive bonds properly. Extra-long planks were phased out for the same reason; no adhesive could reliably restrain them through seasonal movement.

Modern vinyl performs exceptionally well when you:

- Use a full hard-set adhesive

- Level the subfloor

- Moisture test the slab

- stick to 1.2–1.5 m plank lengths

Issues with Solid Timber & Engineered Timber Flooring

Timber and engineered timber are stunning, but they behave differently from every other flooring type. Because it absorbs and releases moisture, most issues come back to environmental conditions rather than the product itself.

The most common things people notice are:

- Cupping or crowning

- Seasonal gaps in winter

- Tight boards are losing their micro-bevel

- Slight unevenness across wide areas

The big fix is acclimatisation of your timber floor. Bring the boards into the home, let them breathe and give them time to adjust to your indoor humidity. Laying timber straight from a warehouse or cold truck is when trouble starts.

Floating timber should be tanked the same way as laminate: builder’s plastic, underlay, then trim it back. For direct stick, moisture-test the slab and use the correct rolled-on barrier and matching adhesive.

Daily habits matter too. Timber will scratch under shoes, dragged furniture, pets or grit; felt pads and regular sweeping go a long way.

Actual failures, such as veneer delamination, are extremely rare and almost always caused by hidden moisture, such as leaks or damp slabs.

Timber becomes one of the most reliable floors you can buy when you:

- Acclimatise properly

- Protect against moisture

- Follow installation rules exactly

Issues with Bamboo Flooring

Bamboo flooring looks like timber and installs like timber, but it isn’t timber; it’s a grass. As a result, it reacts to humidity far more aggressively than most people expect. Nearly every bamboo issue I’ve seen comes back to how quickly it absorbs and releases moisture.

In humid or tropical environments, bamboo tends to grow. In dry or air-conditioned homes, it shrinks. When it’s not acclimatised long enough, you’ll see things like peaking, tight joints, gaps or slight lifting at the edges.

- Humid areas – boards widen and press into expansion gaps

- Dry areas – boards shrink and open visible gaps

The fix is simple: bamboo needs longer acclimatisation than timber. In some regions, it requires weeks, not days. I once worked with a retailer who never had bamboo issues purely because they enforced a long acclimatisation period. Same product, completely different outcome.

Modern bamboo coatings are tough, but scratch-resistant doesn’t mean scratch-proof. Dragged furniture, grit and sharp objects will still mark the surface.

Bamboo performs beautifully when you treat it as a living material: acclimatise properly, leave the correct expansion gaps, and protect the surface. Lay it the day it arrives, and you’re asking for trouble.

Additional Considerations

Don’t Install Flooring Under Fixed Cabinets

- This is a big mistake I see in kitchens.

- Floating floors must be free to move.

- If you pin them down by installing cabinets on top, the expansion has nowhere to go except up — and you end up with a giant bubble or ridge in the middle of the room.

- Floors should go to the cabinets, not under them.

Understand Normal Behaviour vs Real Problems

Some things aren’t failures — they’re just normal.

Normal behaviour:

- Timber seasonal gaps that close again

- Tiny hybrid movement across the raft

- Slight vinyl contraction in cold mornings

- Minor hollow spots over chipboard (within reason)

Not normal:

- Peaking

- Persistent gaps that don’t close

- Moisture readings jumping dramatically in one spot

- Boards breaking

- Boards lifting

- Strong ridges or pressure points

- Floor moving independently of the subfloor

Learn the difference and you’ll save yourself a lot of stress.

Most Flooring Problems Are Preventable

After all these years in flooring, I can say this confidently: the products themselves rarely let you down. Laminate, hybrid, vinyl plank, engineered timber, bamboo, they’re all better built than they’ve ever been, even the budget ranges.

Where things usually go wrong is underneath the surface. A slab that isn’t flat, moisture that isn’t checked, skipped acclimatisation, or one of those small installation rules getting ignored because someone’s in a rush.

Floors are meant to be lived on, not babysat. Get the basics right; protect the slab, level the subfloor, follow the install rules — and your floor will behave exactly the way it’s supposed to for years to come.

And if you ever need a hand comparing products or understanding what’s happening with your subfloor, we’re always here to help.

FAQ

Uneven slabs, moisture in the concrete, skipped acclimatisation, wrong adhesives, inadequate expansion gaps and building movement cause most flooring failures, not product defects.

Hybrid gaps or peaking usually come from moisture rising through the slab, blocked expansion gaps, or subfloors outside flatness tolerance. Thin hybrids on second-storey bounce can also cause joint stress.

This is almost always moisture. Laminate needs builder’s plastic over concrete and the correct raft size. Skipping moisture protection or laying on a damp slab leads to swollen joins.

Vinyl plank reacts to temperature. Early loose-lay products moved a lot. Modern vinyl should be installed with a full hard-set adhesive to stop seasonal movement and gapping.

Yes. Timber and bamboo absorb and release moisture. Acclimatisation prevents cupping, crowning and seasonal gaps. Bamboo needs the longest acclimatisation of all flooring types.

Absolutely. Laminate, timber, bamboo and even hybrid require expansion gaps so the floor can move naturally. Blocking these gaps causes peaking and buckling.

No. Floating floors must stay free to move. Cabinets pin the floor down, leading to major expansion problems and visible humps.

Any installation outside the manufacturer’s guide: missing moisture barriers, no expansion gaps, wrong adhesive, unlevel subfloors, skipped acclimatisation or exceeding raft size limits.

Uneven slabs, moisture in the concrete, skipped acclimatisation, wrong adhesives, inadequate expansion gaps and building movement cause most flooring failures, not product defects.

Hybrid gaps or peaking usually come from moisture rising through the slab, blocked expansion gaps, or subfloors outside flatness tolerance. Thin hybrids on second-storey bounce can also cause joint stress.

This is almost always moisture. Laminate needs builder’s plastic over concrete and the correct raft size. Skipping moisture protection or laying on a damp slab leads to swollen joins.

Vinyl plank reacts to temperature. Early loose-lay products moved a lot. Modern vinyl should be installed with a full hard-set adhesive to stop seasonal movement and gapping.

Yes. Timber and bamboo absorb and release moisture. Acclimatisation prevents cupping, crowning and seasonal gaps. Bamboo needs the longest acclimatisation of all flooring types.

Absolutely. Laminate, timber, bamboo and even hybrid require expansion gaps so the floor can move naturally. Blocking these gaps causes peaking and buckling.

No. Floating floors must stay free to move. Cabinets pin the floor down, leading to major expansion problems and visible humps.

Any installation outside the manufacturer’s guide: missing moisture barriers, no expansion gaps, wrong adhesive, unlevel subfloors, skipped acclimatisation or exceeding raft size limits.