Hybrid flooring has taken off in Australia because it ticks so many boxes: waterproof, durable, stylish, warm underfoot and easy to install. But even with all its advantages, hybrid flooring still has fundamental problems when installed in the wrong environment or without following the rules. The good news? Almost every hybrid issue is preventable once you understand why it happens and how to avoid it.

After years on the tools and years more helping homeowners fix flooring failures, I can tell you one thing confidently: hybrid floors don’t break on their own. Something underneath or around them is causing stress at the joints, and once you know what to look for, the fixes are simple.

Critical Points

- Most problems with hybrid flooring stem from the site or the installation and not from manufacturing faults.

- Silica hydrosis (moisture and chemical vapour rising from concrete) is the number one cause of joint failure.

- Peaking occurs when expansion gaps are blocked, silicone traps the floor, or slab dips force the hybrid to bend.

- Thin hybrid floors struggle on upper levels because second-storey bounce transfers stress into the joints.

- SPC cores handle stress better than WPC aerated cores.

- Always use builder’s plastic over concrete, even if the underlay has a membrane.

- Level the subfloor properly and choose the right thickness for upstairs installs.

- Follow the installation rules exactly, and hybrid floors perform beautifully for years.

Alkalinity Hydrolysis: The Hidden Hybrid Killer

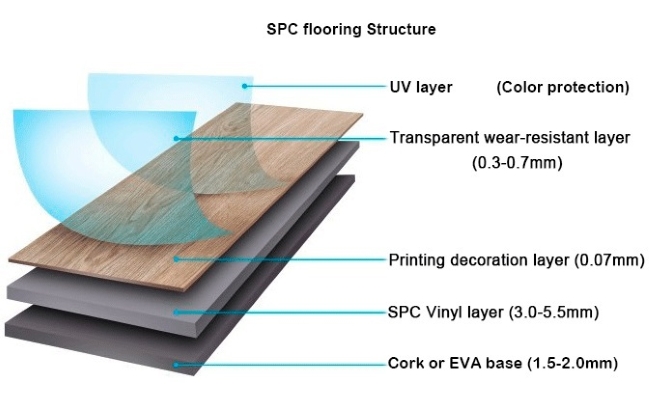

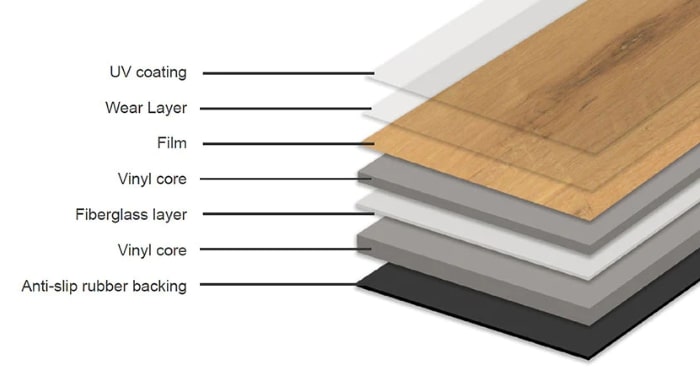

This is the big one. Hybrid floors are built with either a stone-plastic composite (SPC) or a wood-plastic composite (WPC) core. No matter the brand or the core type, the joints and the locking system are always the weakest part of the product. If moisture or chemicals rise up through the concrete slab, they head straight for those joins. That process is called Alkalinity hydrolysis, also known as silica hydrolysis.

Here’s what it does:

- Softens the joints

- Weakens the locking system

- Causes joint failure

- Creates peaking at the joins

- Eventually leads to chipping and breakage

And here’s the kicker: It’s not a product fault. It’s a site issue.

Even the best hybrid floors in the world will fail if the slab underneath is pushing moisture or alkaline vapour upward into the joints. The good news?

The fix is embarrassingly simple:

Always install builder’s plastic under the underlay. Even if your underlay claims to have a built-in moisture membrane, you still install builder’s plastic first. It’s cheap, it’s fast, and it prevents 95% of hybrid joint failures before they ever start.

Hybrid Flooring Peaking (and Why It Happens)

Hybrid doesn’t expand as much as laminate or timber, but it still moves a little.

When the floor is trapped, or the subfloor isn’t flat, you’ll end up with:

- Slight upward pressure at the joins

- Raised edges

- Boards that rock back and forth

- A ridge where boards meet

Most peaking cases come down to a handful of installer mistakes:

- No expansion gaps

- Hybrid is installed tightly to the walls

- Silicone is used where it shouldn’t be

- Skirting boards or trims pinned to the floor

- Heavy furniture placed too early

- Subfloor dips create pressure points

Hybrid flooring is. If you force it to bend over dips or humps in the slab, something’s going to give, and it’s always the joints.

Thin Hybrid on Second Storeys: A Common Failure

This is one that most people don’t even think about until the floor starts misbehaving.

Hybrid performs best on concrete because concrete is solid and stable. But on a second storey in the absence of concrete, especially over chipboard, yellow tongue, or older substrate boards, you get natural “bounce” in the structure. You won’t feel the bounce underfoot.

But the floor will.

Every tiny movement transfers stress straight into the hybrid’s joints. If the product is thin or has a lot of plasticiser in it, those joins eventually:

- Peak

- Lift

- Weaken

- Or break entirely

So how do you know if a hybrid is too weak for upstairs?

A quick rule of thumb:

- White or very pale cores → more plasticiser → weaker joints

- Grey or darker cores → more stone content → stronger joints

Not perfect, but surprisingly accurate.

So for upper levels:

- SPC should be at least 7 mm

- Aerated cores should be 9–10 mm

Install a 5 mm+ hybrid upstairs, such as Eclipse Atlantis Hybrid, especially on a floor with bounce, and don’t be shocked when the joins start misbehaving. The structure underneath moves more than the hybrid can handle.

Solid Core vs Aerated Core (SPC vs WPC)

Let me keep this simple, because this one shapes many hybrid performance issues.

SPC (solid stone-plastic composite):

- Thinner

- Stiffer

- Stronger joints

- Heavier

- Great on concrete slabs

WPC / Aerated core:

- Softer

- Thicker

- More forgiving underfoot

- Weaker joints

- Absolutely needs thickness upstairs

Why Hybrid Joins Break

Hybrid fails far more often due to the subfloor than to the product.

The most common causes are:

- Dips and humps in the slab

- Second-storey movement

- Moisture rising into the joints

- Installer skipping builder’s plastic

- Installer not checking flatness

- Boards dragged or forced into place

- Planks hammered in from bad angles

- Subfloor bounce stresses joints over time

It’s rarely manufacturing. Most hybrid on the market today is made to a very high standard.

The floor underneath determines whether the hybrid thrives or fails. For a better understanding, we recommend reading: Why Subfloor Preparation Is Important For Long-Lasting, Beautiful Floors.

Problems Are Almost Always Site-Related

People often blame the boards because the problem shows up there. But hybrid floors don’t break in isolation. Something in the environment is causing stress that the locking system eventually can’t tolerate.

These are the most common site-related causes I see:

- Slab not within tolerance

- Flooring installed too soon after delivery (cold to warm environment)

- No moisture protection under the underlay

- No builder’s plastic

- Subfloor bounce is not reinforced

- Skirting boards nailed into the floating floor

- Hybrid installed under fixed cabinetry

- Incorrect expansion gaps

- Silicone trapping the perimeter

- Heavy furniture placed before the floor settles

- Extreme heating or cooling during installation

- Upper-storey movement amplifying stress

Every one of those issues forces the hybrid to flex or strain at the joints, and eventually, the joints lose the battle.

How to Prevent Hybrid Flooring Problems

If you want to avoid the big problems with hybrid flooring, choosing the right product for the right environment, and installing it correctly, is half the battle. Hybrid is incredibly reliable when it fits the space it’s going into, and a headache when it doesn’t.

Here’s what I recommend after years of seeing both the great installs and the disasters:

- On concrete: almost any hybrid works well as long as you use proper moisture protection with an even subfloor.

- On second storeys: choose thicker products. The natural bounce in upper floors needs a hybrid with a stronger core and thicker profile.

- Avoid very thin hybrids (below 5 mm) in high-movement homes: they don’t have the strength in the joints to handle ongoing structural flex.

- Never rely solely on an underlay membrane — always use builder’s plastic. I’ve seen too many failures from skipping this step.

- Level your subfloor properly: hybrid is stiff and will not forgive dips, humps or twisted substrates.

- Follow raft size rules: every manufacturer has them for a reason.

- Avoid silicone unless the brand specifically allows it: silicone can trap the perimeter and cause peaking.

- Make sure your installer actually understands hybrid: not all installers who lay laminate should be laying hybrid.

- Choose brands with strong locking systems and higher stone content: stronger cores = better long-term joint performance.

- Choose the right thickness for upper levels: 7 mm+ for SPC, 9–10 mm for aerated cores.

- Leave proper expansion gaps and check them room-to-room.

- Follow installation rules to the letter.

- Avoid silicone unless the brand gives you the green light.

- Never install hybrid under fixed cabinetry — it must float freely.

- Do not force the joins or hammer boards at angles.

Do all of that, and hybrid performs beautifully; warm, quiet, durable, waterproof, and stable for years.

This is a Brilliant Product Category

I can tell you this confidently: hybrid is a brilliant product when it’s treated the way it’s meant to be treated.

It’s waterproof, tough, stable, quiet underfoot and suits most Australian homes beautifully. But the issues almost never come from the boards themselves. They come from what’s underneath the floor, around the floor, or the way it was installed.

When hybrid fails, the problem usually starts long before the floor goes down. The good news? Almost every problem with hybrid flooring is preventable.

Get the basics right, and your hybrid floor will behave exactly the way it’s supposed to for many years.

FAQ

Most hybrid flooring problems start underneath the product, not in the boards themselves. The big ones are slab moisture, alkalinity hydrolysis (silica hydrosis), uneven subfloors, blocked expansion gaps, and thin hybrid being used upstairs where there’s natural bounce. All of these put stress on the joints, which eventually fail.

Hybrid joints break when the locking system is weakened by moisture, chemical vapour from the slab, subfloor dips, second-storey movement, or boards being forced together during installation. It’s seldom a manufacturing issue; 95% of joint failures are due to site conditions or installation shortcuts.

Silica hydrosis happens when moisture or alkaline vapour rises from a concrete slab and softens the hybrid’s locking system. It’s the number one cause of hybrid joint failure. The fix is simple: always install builder’s plastic under the underlay, even if the underlay claims to have a moisture membrane.

Peaking usually means the floor can’t move the way it needs to. Common causes include no expansion gaps, silicone trapping the perimeter, skirting boards pinned to the floor, or the hybrid being forced over slab dips. The hybrid board is stiff; if it’s bent over uneven spots, the joints push upward.

Upper levels have natural “bounce” because they’re usually built on chipboard or yellow tongue instead of concrete. Thin hybrid floors (5–6 mm) struggle with this movement. For upstairs installs, SPC should be at least 7 mm, and WPC/aerated cores should be 9–10 mm.

Yes, hybrid flooring is waterproof, but the slab underneath is not. Water or alkaline vapour rising through concrete can damage the locking system even though the planks themselves are fine. Waterproof doesn’t mean moisture-proof underneath.

Absolutely, yes. Lay builder’s plastic over every concrete slab before installing hybrid flooring. Even if the underlay includes a membrane, you still use builder’s plastic. This single step prevents most joint failures caused by slab moisture and alkalinity.

Yes. Hybrid flooring still expands and contracts slightly with temperature changes. If you don’t leave the correct expansion gaps—or if silicone or skirting boards trap the perimeter—you’ll end up with peaking and ridges.

No. Hybrid is a floating floor and must be able to move. If you install cabinets on top of it, you’ll pin it down and the movement will force the planks to lift or buckle somewhere else.

Because upper floors flex. The small bounce in second-storey substrates transfers straight into the hybrid’s joints. Thin products or weaker cores can’t absorb that movement, so joins peak, lift or break.